Before introducing the production process of lipsticks, it is necessary to introduce the main ingredients of lipsticks and the main packaging of lipsticks.

Main Ingredients

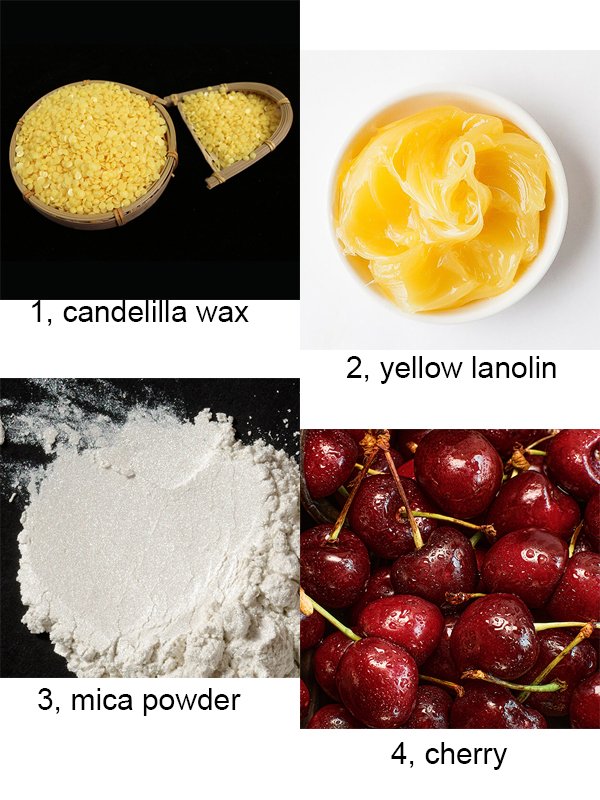

Lipstick is mainly made of wax, oil, grease, pigment, and so on.

- wax usually involves some combination of three types – bees wax, candelilla wax, or camauba. Wax allows the mixture to be formed into easily recognizable cosmetic shapes.

- oils such as mineral, caster, lanolin, or vegetable are added to the wax.

- pigment and fragrance are added. And lipsticks come in a wide range of colors.

- preservatives and antioxidants are added, which prevent lipstick from becoming rancid.

- other ingredients may be also added, which make the lipstick smoother or glossy or to moisten the lips.

Just as there is no standard size or container shape for lipsticks, there is also no standard type or proportion of ingredients used.

In addition to the basic/base ingredients (waxes, oils, and antioxidants), the number of supplemental materials varies greatly. The ingredients themselves range from complex organic compounds to completely natural ingredients, the proportions of which determine the characteristics of the lipstick.

In general, waxes and oils make up about 60% (by weight) of a lipstick, with pigments and others making up the other 25% (by weight). Fragrances are always added to lipsticks, but makeup one percent or less of the mixture.

Main Packaging

The main packaging of lipsticks is the tube.

The tubes that hold lipstick range from inexpensive plastic dispensers for lip balms to ornate metal for lipsticks. Sizes are not uniform.

The tubes have two parts, a cover, and a base. The base is made up of two components, the twisting or sliding of which will push the lipstick up for application.

There are three separate steps:

I. Melting and mixing the raw materials

The raw ingredients are melted and mixed separately

- the 1st mixture contains the solvents,

- the 2nd mixture contains the oils,

- the 3rd mixture contains the fats and waxy materials.

These are heated in separate stainless steel or ceramic containers.

The 1st mixture (solvent solution) and the 2nd mixture (liquid oils) are then mixed with the color pigments. we call this the 4th mixture.

Then, the 4th mixture passes through a roller mill, grinding the pigment to avoid a “grainy” feel to the lipstick. The 4th mixture is stirred for several hours; at this point, we use vacuum equipment to withdraw the air.

Last, the 4th mixture is added to the 3rd mixture (hot wax mass) until a uniform color and consistency is obtained, we call this the 5th mixture, and the 5th mixture (fluid lipstick) can finally be strained and molded, or it may be poured into pans and stored for future molding.

II. Pouring the mixture into the tube

The 5th mixture is dispensed into a mold, which consists of the bottom portion of the metal or plastic tube and a shaping portion that fits snugly with the tube.

Lipstick is poured “upside-down” so that the bottom of the tube is at the top of the mold. Any excess is scraped from the mold.

III. Packaging the product for shipment

There are a variety of packaging options available, ranging from bulk packs to individual packs, including packaging as a component in a makeup kit or special promotional offering.

- After tubes are filled, they are inserted into open paperboard boxes.

- The boxes are cased and shipped to warehouses and stores.

Quality Control

Lipstick is an ingested cosmetic product with strict control over the ingredients and manufacturing process.

- each batch of ingredients is tested for quality as it is brought into the factory.

- patrol inspectors and inspectors of workshop do patrol inspection during production, especially the appearance and color of the final product.

- the laboratory also checks samples of final product.

In addition, there are two special tests for lipsticks: heat test and breakage test.